Digital Industry Models for Manufacturing: Affordable, Agile, and High ROI

Learn About Digital Industry Models for Manufacturing: Affordable, Agile, and High ROI

Are you a marketer in the manufacturing industry? Are you interested in understanding the solutions to optimize efficiency and create an agile workflow for reducing costs, waste, and time? Look no further than digital industry models.

Digital Industry Models offer manufacturing companies affordable ways to reduce overheads, improve agility and gain access to data-rich insights on all stages of production.

They quickly become the favored choice for many modern manufacturing professionals as they drive performance efficiencies throughout their teams. In this blog post, we’ll take a closer look at how these digital tools can help you achieve maximum value from your current production model while reaching new heights of cost control.

Understanding Digital Industry Models for Manufacturing Companies

In the rapidly evolving technological landscape, manufacturing companies must prioritize understanding digital industry models to remain competitive and adapt to shifting market dynamics.

Organizations can optimize production processes, streamline supply chains, and personalize customer experiences by harnessing the power of data-driven insights and smart technologies.

Collaboration across departments is crucial to developing effective digital strategies, as it encourages innovation and supports sustainable business practices.

Embracing digital transformations allows manufacturing companies to stay ahead of disruptive trends, facilitating long-term growth while reducing operational inefficiencies.

Ultimately, comprehending digital industry models equips manufacturing businesses with the knowledge and tools to shape their digital journeys and thrive in a constantly changing environment.

Benefits of Adopting a Digital Industry Model

Adopting a digital industry model can profoundly impact a business organization’s efficiency and competitiveness.

By leveraging innovative technologies and streamlining workflows, companies can reap considerable benefits in cost reduction, improved operational efficiency, faster decision-making processes, and enhanced customer experience.

Furthermore, the digital industry model allows businesses to adapt to ever-evolving market demands and effortlessly capitalize on emerging market opportunities. With real-time data analytics, companies can make informed decisions to drive growth and stay ahead of the competition.

Digital transformation helps businesses achieve long-term sustainability and fosters a culture of innovation, empowering them to thrive in today’s technology-driven world.

– Cost-efficiency

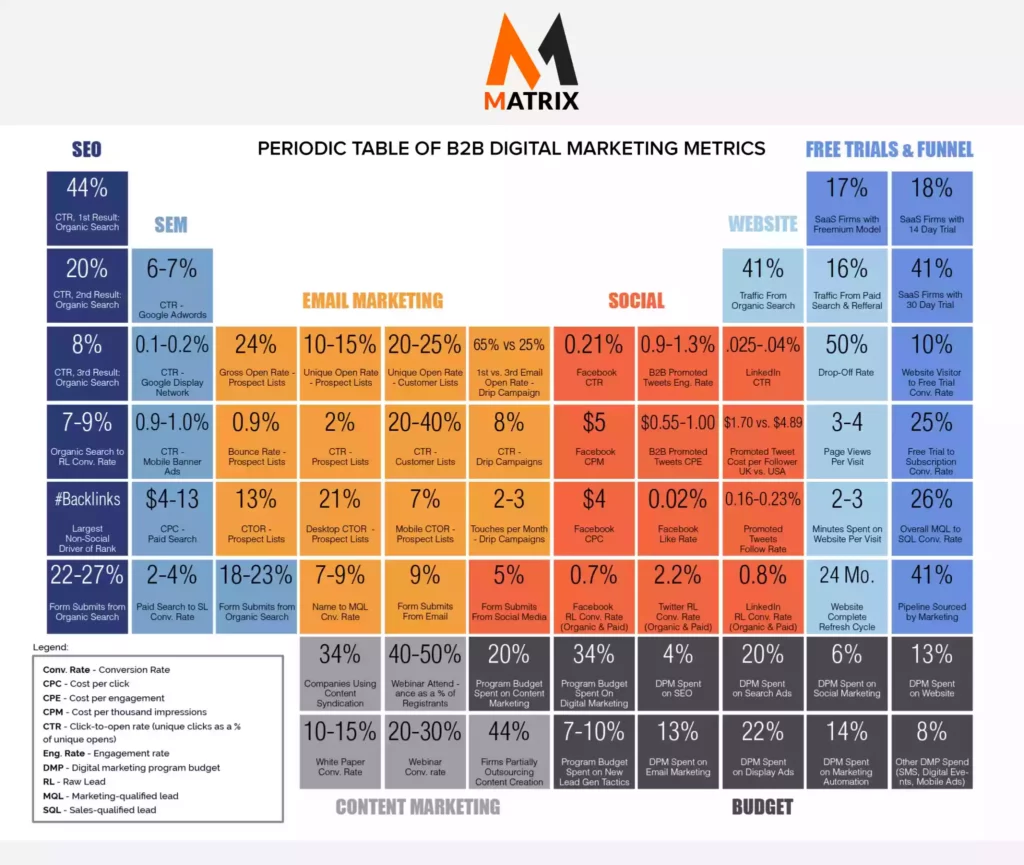

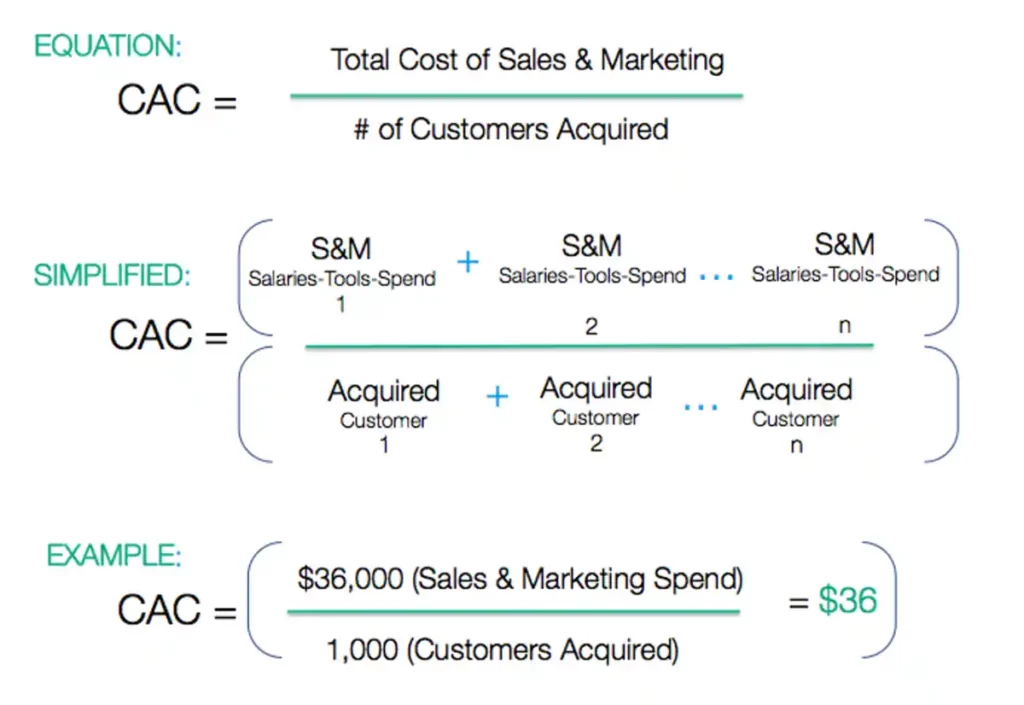

Knowing your cost to acquire a customer will help you focus on balance and testing.

In today’s fast-paced and competitive business landscape, achieving cost efficiency is paramount for organizations of all sizes. Minimizing expenses without sacrificing the quality of products or services directly contributes to increased profitability and long-term success.

Organizations must strategically evaluate their operations, identify areas of potential improvement, and implement innovative solutions to optimize resource allocation.

By embracing a cost-efficient mindset and fostering a culture of continuous improvement, businesses can maintain an edge in their respective industries and set the stage for sustainable growth and operational excellence.

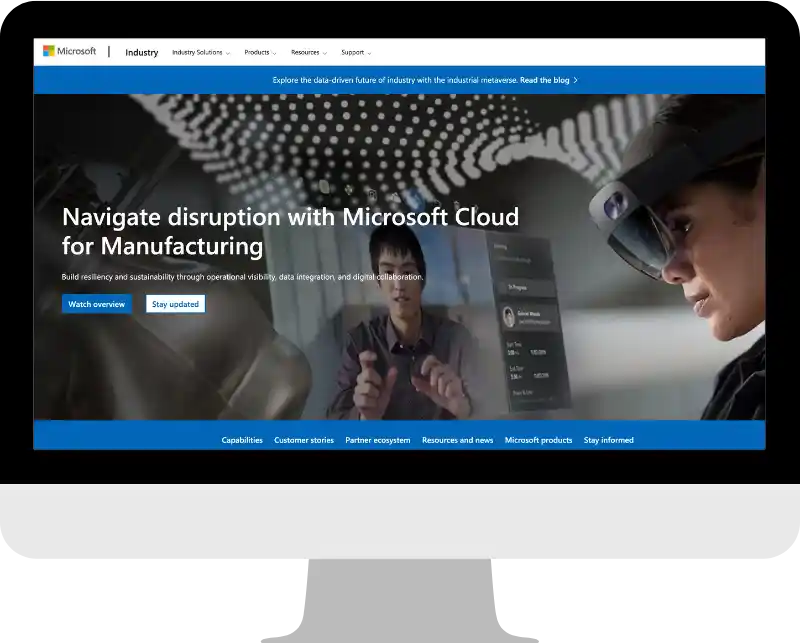

Navigate disruption with Industry Solutions for Manufacturing.

Build resiliency and sustainability through operational visibility, data integration, and digital collaboration.

Adopting a professional approach to driving cost efficiency can lead to remarkable financial gains while enhancing organizational performance and stakeholder satisfaction.

– Agility and Flexibility

In an ever-changing digital landscape, manufacturing companies have found innovative ways to stay competitive. Agility and flexibility are essential components of success, and many leading firms are now leveraging digital industry models to maintain an edge in the markets.

Automated workflow solutions allow manufacturing teams to shift with changing trends and scale processes up or down as needed with minimal fuss.

Manufacturers can save time and money using agile and flexible systems and processes while delivering a top-notch experience today and tomorrow.

– Increased Quality and Productivity

In the modern world, digital industry models are increasingly in demand due to their potential to help manufacturing companies attain higher levels of quality and productivity.

Adopting a digital data-driven model can help manufacturers increase uniformity across production processes, leading to fewer defects, improved efficiency, and ultimately higher quality goods.

Companies can reduce waste and maximize productivity with better insights into how materials are used throughout different process steps. Thus, an integrated digital industry model provides a prime opportunity for companies looking to kick their business up a notch.

Challenges to Overcome When Implementing a Digital Industry Model

In today’s fast-paced business environment, implementing a digital industry model has become essential for companies striving to maintain a competitive edge. As organizations undertake this transformative journey, they face several challenges that must be meticulously addressed to ensure a smooth transition.

One of the prominent concerns is overcoming the resistance from employees who might perceive the change as a threat to their jobs or fear a steep learning curve. Strong change management strategies, employee training programs, and effective communication channels must be implemented to alleviate these concerns while fostering a supportive work environment.

Technological readiness is another critical aspect, as the successful integration of cutting-edge applications and infrastructure calls for active participation from diverse stakeholders, including IT personnel and end-users.

Additionally, ensuring data security and privacy is a central part of the adoption process, requiring companies to reassess their security protocols and protection measures. Collaborating with experienced partners and engaging in continuous improvement initiatives can help organizations navigate the complex landscape of digital transformation and ultimately harness the full potential of a digital industry model.

Achieving Success with a Digital Industry Model for Your Manufacturing Company

In today’s rapidly evolving technological landscape, achieving success for your manufacturing company requires embracing a digital industry model. As a forward-thinking business leader, it is crucial to recognize the transformative potential of digitization in streamlining operations and enhancing your company’s overall competitiveness.

A digital industry model seamlessly integrates advanced technologies such as the Internet of Things (IoT), artificial intelligence, and big data analytics to optimize the production lifecycle. By harnessing these innovations, manufacturers can improve efficiency, reduce waste, and produce higher-quality products that meet the ever-changing demands of modern consumers.

Adopting a digital industry model fosters an environment of continuous improvement by facilitating real-time access to critical data that drives informed decision-making.

Ensuring your company thrives in the digital age demands the proactive pursuit of technological advancements and a commitment to the digital transformation that drives sustainable success.

Examples of Companies that Have Succeeded with the Implementation of Digital Manufacturing Models

Implementing digital manufacturing models such as Industry 4.0 has revolutionized automotive manufacturing, aeronautics, and shipbuilding industries.

Companies such as McLaren Automotive, Airbus, and Meyer Werft are all examples of industry leaders who have successfully integrated digital transformation processes into their workflows.

Their investment in smarter data acquisition and analysis systems has allowed them to increase productivity, reduce production time, and lower costs. With the help of AI-driven analytics and automated robotic systems, these companies have transformed their operations from traditional mechanisms to state-of-the-art facilities led by related technologies.

This shift towards augmented intelligence offers improvements in business processes that were previously unattainable with traditional methods, improving efficiency and cost benefits simultaneously.

The 7-Step Method for implementing digital industry models

Organizations must adapt and innovate to stay competitive in today’s rapidly evolving digital landscape. One proven approach to achieving this is implementing digital industry models through the 7-step method, which promotes efficiency and effectiveness in transforming your business.

This approach provides a structured and systematic framework, ensuring that companies undergo a comprehensive analysis of their digital maturity, pinpointing the areas where improvements can significantly impact business performance.

It expertly maps out the digital transformation journey, identifying key challenges to scaling and sustaining long-lasting improvements.

By leveraging this method, businesses can expertly navigate their digital transformation, harnessing the power of emerging technologies to drive innovation, growth, and, ultimately, success.

What are the 9 types of digital business models?

The nine types of digital business models include marketplace, subscription, platform, freemium, affiliate, advertising, direct sales, on-demand service, and peer-to-peer sharing economy models.

Marketplace Models involve connecting buyers and sellers in a single platform. This model enables customers to compare prices across various products and services. Examples of this model are eBay or Amazon.

Subscription Models involve customers paying a fixed fee to access a product or service over a certain period. Services such as Spotify or Netflix are examples of this model.

Platform Models provide an integrated platform connecting users with third-party developers and services. This model allows users to customize their experience within the platform while creating new business opportunities. An example is Apple’s App Store or Google Play Store.

Freemium Models involve providing basic services for free but requiring customers to pay for upgrades if they want more features or better performance from the product or service. Dropbox or LinkedIn are examples of this type of model.

Affiliate Models involve companies paying commissions to other partners who drive traffic or sales to their website through referral links or ad campaigns. Amazon’s affiliate program is an example of this type of business model.

Advertising Models involve displaying ads within the product or on websites in exchange for payment from advertisers based on the number of views they receive from customers using the product/service. Google Ads is an example of an advertising model in practice today.

Direct Sales Models focus on providing products/services directly to consumers without intermediary parties such as retailers or distributors involved in the process. Apple’s iTunes Store is an example of this digital business model in action today.

On-Demand Service Models allow customers to access various services without committing to long-term contracts by offering them at extremely reasonable rates with convenient delivery options Uber Eats and Instacart are good examples here too!

Peer-to-Peer Sharing Economy Models enable individuals (or small groups) to share resources, including physical assets, skillsets, or ideas, with others at minimal cost – popularly known as ‘collaborative consumption’. Airbnb is a prime example here!

Microsoft and Matrix Marketing Group industry models for manufacturing firms

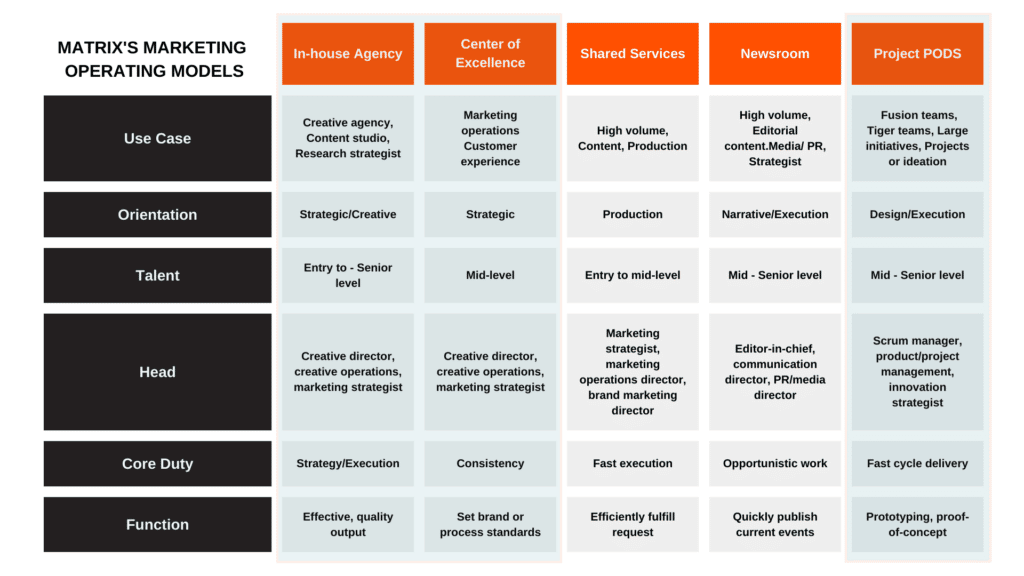

Microsoft and Matrix Marketing Group are two corporations that have developed successful industry models designed to improve the operation of manufacturing companies.

These models provide the latest in digital transformation strategies, providing manufacturers with the tools needed to enhance asset performance, reduce waste, decrease costs, and achieve greater revenue output from their production processes.

With Microsoft and Matrix Marketing Group’s help, manufacturers can increase operational efficiency and sustain competitive advantage in today’s competitive market.

Overall, digital industry models have helped to revolutionize the manufacturing industry. With the right model, companies can become more cost-efficient while increasing their quality and productivity. Despite these many benefits, organizations must know the challenges in implementing a model.

Companies that have succeeded in implementing digital manufacturing models are examples and role models for organizations looking to do the same.

Once you have identified your needs, Microsoft and Matrix Marketing Group have developed an innovative 7-step method for implementing digital industry models that balance cost-effectiveness, agility, flexibility, and improved quality control.

Recognizing how this new technology can boost conversions and sales is important. Make sure to grab our helpful sales tool today to reap all of these great rewards!

General FAQs

What is a Digital Industry Model?

A digital industry model is a process that utilizes digital transformation strategies to improve the operations of manufacturing companies. These models leverage emerging technologies such as artificial intelligence, analytics, and robotics to drive innovation, growth, and success. Using these tools, manufacturers can increase operational efficiency, reduce waste, decrease costs, and achieve greater revenue output from their production processes.

How do Digital Industry Models help manufacturers?

Digital industry models provide manufacturers with the latest digital transformation strategies to help them gain a competitive edge in today’s ever-evolving market. By utilizing these models, manufacturers can increase asset performance and optimize their production processes for maximum productivity and cost-effectiveness while decreasing waste and achieving greater revenue output.

What are the main benefits of implementing a Digital Industry Model?

The main benefits of implementing a digital industry model include increased operational efficiency, improved quality control, agile and flexible processes, reduced costs due to optimized production processes and decreased waste materials, and enhanced customer satisfaction by providing products faster with better quality.

What is the 7-Step Method for implementing a Digital Industry Model?

The 7-Step Method for implementing a digital industry model is an expertly mapped-out framework that provides businesses with a structured approach to digital transformation. This method entails analyzing the company’s digital maturity level to determine areas where improvements can significantly impact business performance. It then guides how to harness emerging technologies such as AI-driven analytics and automated robotic systems to scale up performance efficiently.